The AI Revolution in Global Logistics — How Automation Will Reshape Freight by 2030

Why AI Is Transforming Global Logistics

Global logistics is entering a decade of structural change, driven by digitalisation, volatile trade patterns, climate-related disruption, and rising operational pressure. Artificial intelligence has moved beyond experimentation and is now becoming the intelligence layer behind modern freight networks. By 2030, AI is expected to operate as the central nervous system of global transport—linking ships, trucks, trains, warehouses, terminals, and border systems into one coordinated ecosystem. This transition is accelerating because traditional logistics models can no longer respond effectively to today’s complexity.

1.1 Why Traditional Supply Chains Are Under Pressure

For decades, supply chains were designed around linear planning and static schedules. These models worked in relatively stable markets where demand was predictable and disruptions were limited. In recent years, however, global logistics has faced repeated stress. Congested ports, geopolitical tension, extreme weather events, labour shortages, and container imbalances have exposed the weaknesses of manual coordination.

At the same time, demand patterns have become far less predictable. Production cycles shift faster, regional shocks spread globally, and delays in one location often trigger downstream disruption. Because of this, logistics teams must react earlier and with greater accuracy. Manual planning tools struggle to operate at this speed.

AI addresses this gap by analysing real-time data from ports, vessels, rail terminals, trucking networks, customs systems, and satellite feeds. As a result, companies gain earlier visibility into risks and can adjust operations before disruptions escalate.

Artificial intelligence is reshaping global logistics by connecting transport modes into one intelligent network.

1.2 From Reactive Planning to Predictive Logistics

One of the most important changes AI introduces is the shift from reactive to predictive logistics. Instead of responding after delays occur, AI-driven systems continuously evaluate signals such as weather forecasts, vessel movements, congestion trends, and carrier performance. Based on these inputs, predictive models estimate where and when disruptions are likely to happen.

For example, if an AI system detects that a vessel approaching Northern Europe is likely to be delayed due to weather conditions, inland schedules can be adjusted in advance. Rail departures may be rescheduled, truck capacity reassigned, and terminal resources reallocated. Consequently, congestion is reduced and multimodal transfers remain stable.

Predictive logistics also improves cost control. Companies using AI-based forecasting report fewer detention and demurrage charges, better labour planning, and more efficient use of terminal capacity. McKinsey — Global Supply Chain AI Outlook (2024)

1.3 Why AI Has Become a Competitive Necessity

AI is no longer a differentiator reserved for advanced operators. Instead, it is becoming a baseline requirement for companies competing in global logistics. Organisations that use AI-driven planning achieve more reliable ETAs, smoother coordination across transport modes, and stronger service consistency. In contrast, companies without predictive systems often remain trapped in reactive decision-making.

AI improves several critical areas simultaneously:

-

schedule reliability

-

demand forecasting accuracy

-

route stability

-

operational transparency

-

cost efficiency

-

risk anticipation

In addition, AI automates labour-intensive processes such as dispatch planning, document verification, and equipment allocation. This reduces operational strain and allows logistics teams to focus on strategic decisions rather than daily problem-solving.

1.4 The Role of AI in Multimodal Coordination

Modern supply chains rely heavily on multimodal transport, where sea, rail, and road must operate in close coordination. Traditionally, these modes functioned in silos, which increased the risk of cascading delays. AI changes this by creating a unified decision layer that synchronises all modes in real time.

If a vessel arrival time changes, AI recalculates rail and truck schedules automatically. When port congestion increases, alternative routing options are evaluated instantly. Meanwhile, if weather affects road transport, the system can prioritise rail segments where possible. As a result, multimodal corridors become more stable and predictable.

1.5 How Arta Rail Supports AI-Driven Logistics

While AI delivers predictive intelligence, physical execution remains essential. This is where inland logistics providers play a critical role. Arta Rail supports AI-driven logistics by offering reliable rail–road corridors, multimodal planning, and inland connectivity across key Eurasian routes.

When AI-based systems recommend route adjustments or timing changes, Arta Rail translates those insights into real-world execution. Rail capacity is coordinated, multimodal transfers are aligned, and schedules are adapted to current conditions. Consequently, global shippers benefit from higher reliability even during periods of disruption.

Internal Link (add real URL in WordPress):

Arta Rail — Rail Freight Transit in Central Asia: Faster Connections Through Multimodal Corridors

1.6 AI and the Sustainability Dimension

Sustainability is becoming a core requirement in logistics strategy. AI supports greener freight networks by identifying routing options that reduce fuel consumption and emissions. By comparing thousands of possible paths, AI highlights rail-based and multimodal solutions that lower the carbon footprint of shipments.

In addition, AI improves asset utilisation, reduces empty runs, and optimises terminal operations. These improvements align closely with global ESG objectives and the growing demand for green logistics solutions.

How AI Strengthens Global Logistics

| Focus Area | AI Contribution | Operational Result |

|---|---|---|

| Predictive Planning | Early risk detection | Higher schedule stability |

| Multimodal Coordination | Real-time mode synchronisation | Fewer cascading delays |

| Terminal Efficiency | Automated resource allocation | Faster cargo handling |

| Documentation | AI-driven validation | Shorter clearance times |

| Sustainability | Low-emission route optimisation | Reduced carbon footprint |

2.Core AI Technologies Transforming Logistics (2025–2030)

Artificial intelligence is reshaping global logistics by replacing fragmented, manual systems with intelligent, connected decision layers. Instead of relying on static schedules and delayed reporting, logistics networks are increasingly guided by systems that learn continuously and respond in real time. This transformation is not driven by a single technology. Rather, it is powered by a combination of AI tools that work together to improve reliability, efficiency, and resilience across transport modes.

At the core of this shift are several key AI technologies that are already influencing how freight is planned, moved, monitored, and documented worldwide.

2.1 Predictive Analytics and Demand Forecasting

Predictive analytics represents the most widely adopted AI capability in logistics today. These systems analyse vast datasets drawn from weather services, vessel schedules, port congestion models, rail timetables, trucking telemetry, fuel price movements, geopolitical indicators, and historical trade flows. By processing these inputs simultaneously, AI identifies patterns that human planners cannot detect at scale.

Unlike traditional forecasting tools, predictive models continuously update themselves. As new data arrives, forecasts adjust automatically. This allows logistics teams to anticipate congestion, delays, or demand spikes days or even weeks in advance.

For example, if predictive analytics detect rising congestion at a major port, inland rail schedules can be adjusted early. Warehouses can rebalance labour, and inventory can be repositioned before disruption impacts customers. As a result, companies reduce dwell times, avoid emergency rerouting, and maintain service stability.

Predictive forecasting is particularly valuable in multimodal logistics. When one mode is delayed, AI recalculates the downstream impact on rail, road, and terminal operations. This prevents bottlenecks from spreading across the network.

2.2 Autonomous and Semi-Autonomous Operations

AI-driven automation now extends well beyond basic warehouse robotics. Major ports and logistics hubs are deploying autonomous and semi-autonomous systems to improve throughput and reduce dependency on manual coordination.

Leading terminals use automated stacking cranes, autonomous yard vehicles, and AI-controlled gate systems to optimise cargo movement. These systems prioritise tasks dynamically, adjusting equipment allocation based on real-time congestion and vessel schedules. As a result, terminals achieve faster turnaround times and more consistent operations during peak demand.

In addition, semi-autonomous truck and rail platooning is becoming more common along controlled corridors. Vehicles equipped with AI-assisted driving systems maintain optimal spacing, reduce fuel consumption, and improve safety. Rail operators also benefit from AI-supported signalling and traffic management, which improves network fluidity and reduces delays.

Inside warehouses, computer-vision systems handle scanning, sorting, and quality checks with high accuracy. Machine-learning models decide where goods should be stored based on forecasted demand, reducing unnecessary internal movement and improving picking efficiency.

Predictive analytics and automation help logistics operators anticipate disruptions and improve operational efficiency.

2.3 Digital Twins and Scenario Simulation

Digital twins are becoming a strategic planning tool for complex supply chains. A digital twin is a virtual replica of a logistics network that mirrors real-world operations in real time. By simulating different scenarios, companies can test how disruptions affect their networks before those disruptions occur.

For instance, a digital twin can model the impact of a port closure, rail congestion, extreme weather, or a sudden surge in demand. Logistics managers can then evaluate alternative routes, adjust capacity, and prepare contingency plans without disrupting live operations.

This capability is critical because modern supply chains are highly interconnected. A delay at one node often affects operations far beyond its immediate location. Digital twins reveal these dependencies and help companies prevent cascading failures.

Scenario simulation also supports long-term planning. Companies can assess how changes in trade flows, infrastructure investment, or regulatory environments will influence their networks over time.

2.4 NLP and AI-Driven Documentation

Documentation remains one of the most common sources of delay in international logistics. Bills of lading, commercial invoices, packing lists, certificates, and customs declarations often require manual verification. AI significantly reduces this burden.

Natural language processing systems read, classify, and validate documents automatically. They detect missing information, inconsistencies, and formatting errors before documents are submitted to authorities. As a result, clearance times are shortened and the risk of administrative delays is reduced.

For multimodal shipments crossing multiple borders, document automation is particularly valuable. AI ensures that paperwork remains consistent as cargo transfers between sea, rail, and road. This improves predictability across cross-border corridors.

2.5 AI Routing Engines for Multimodal Networks

Routing decisions have become increasingly complex due to congestion, geopolitical risk, and climate disruption. AI routing engines address this challenge by evaluating thousands of routing combinations in real time.

These systems consider factors such as port congestion, vessel reliability, rail slot availability, border wait times, fuel costs, weather forecasts, and security alerts. Based on this analysis, AI recommends the most stable and time-efficient multimodal route.

For example, if maritime disruption occurs, AI may shift cargo to a sea–rail–road combination. If inland congestion increases, alternative terminals are evaluated instantly. This transforms routing from a reactive task into a proactive strategy.

Routing intelligence is especially valuable for high-value or time-sensitive cargo, where reliability matters more than lowest cost.

2.6 Operational Impact for Multimodal Providers

Multimodal logistics providers benefit strongly from AI integration because their operations depend on precise coordination across modes. While AI delivers the intelligence layer, physical execution remains essential.

Companies such as Arta Rail use AI insights to support rail scheduling, corridor planning, and multimodal transfers. When predictive systems recommend route or timing adjustments, inland operators align rail capacity and road connections accordingly. This reduces dependency on unstable maritime routes and improves overall network resilience.

Internal Link (insert real URL in WordPress):

Arta Rail — Rail Freight Transit in Central Asia: Faster Connections Through Multimodal Corridors

Core AI Technologies and Their Logistics Impact

| AI Technology | Primary Function | Practical Impact |

|---|---|---|

| Predictive Analytics | Forecasts demand and congestion | More stable planning |

| Autonomous Systems | Automates terminals and yards | Faster throughput |

| Digital Twins | Simulates disruptions | Better contingency planning |

| NLP & Document AI | Automates documentation | Faster clearance |

| AI Routing Engines | Optimises multimodal routes | Lower transit risk |

3 . How AI Is Reshaping Global Freight Networks and Decision-Making

As artificial intelligence becomes more deeply embedded in logistics operations, its influence extends beyond individual technologies. AI is now reshaping how global freight networks are designed, coordinated, and managed on a strategic level. Instead of relying on fixed routes and static planning cycles, logistics networks are evolving into adaptive systems that respond continuously to real-world conditions.

This transformation affects not only routing and visibility, but also network resilience, capacity planning, and long-term decision-making across global supply chains.

3.1 From Linear Networks to Adaptive Freight Systems

Traditional freight networks were built around linear flows. Cargo moved from origin to destination through predefined routes, and deviations were handled manually. However, modern trade environments are far less stable. Congestion, weather disruptions, regulatory changes, and geopolitical events can alter optimal routes overnight.

AI enables logistics networks to operate as adaptive systems rather than fixed chains. By continuously analysing operational data, AI identifies changes in network conditions and adjusts routing, scheduling, and capacity allocation automatically. As a result, freight flows become more flexible and less vulnerable to single points of failure.

For example, if congestion builds at a major maritime hub, AI evaluates alternative ports, inland corridors, and multimodal combinations. These adjustments occur before delays cascade across the network, improving overall reliability.

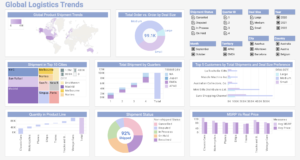

3.2 Real-Time Visibility as a Strategic Asset

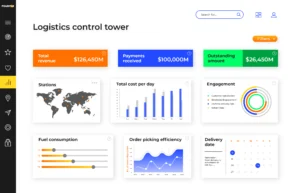

Visibility has long been one of the biggest challenges in global logistics. Cargo often moves across multiple transport modes, each with its own tracking systems. AI resolves this fragmentation by integrating data from ships, trains, trucks, terminals, satellites, and IoT sensors into a single operational view.

Through this unified visibility layer, logistics teams gain real-time insight into cargo location, condition, and estimated arrival times. When disruptions occur, AI recalculates downstream schedules and updates ETAs automatically. This prevents surprises and allows stakeholders to make informed decisions quickly.

Moreover, real-time visibility supports better communication with customers. Shippers receive accurate updates instead of delayed notifications, which improves trust and service quality.

3.3 AI-Driven Capacity Planning and Resource Allocation

Capacity planning is becoming increasingly complex as demand patterns grow more volatile. Seasonal fluctuations, sudden demand spikes, and unexpected disruptions make manual planning inefficient. AI transforms capacity management by predicting future load patterns and aligning resources accordingly.

Machine-learning models evaluate historical volumes, booking trends, vessel schedules, rail slot availability, and regional demand forecasts. Based on these insights, logistics operators can pre-position equipment, allocate labour more effectively, and prevent congestion before it occurs.

For multimodal networks, AI synchronises capacity across sea, rail, and road. If maritime schedules change, inland capacity is adjusted automatically. This coordination reduces idle time, improves asset utilisation, and stabilises throughput across the network.

AI enables real-time visibility and coordination across global freight networks.

3.4 Strengthening Network Resilience Through Predictive Intelligence

Resilience has become a defining priority for global logistics. AI enhances resilience by identifying weak points in freight networks and recommending mitigation strategies. Predictive systems monitor early signals such as rising port congestion, abnormal weather patterns, labour disputes, and geopolitical developments.

When risks increase, AI models simulate alternative scenarios. These simulations reveal how disruptions propagate through the network and which routes or hubs are most vulnerable. As a result, logistics teams can redesign flows proactively rather than reacting under pressure.

For instance, if a key corridor shows increasing risk, AI may suggest diversifying routes or shifting volume toward inland rail corridors. This approach reduces dependency on fragile chokepoints and improves continuity during periods of instability.

3.5 The Strategic Role of Multimodal Operators

Multimodal operators play a critical role in AI-enabled freight networks because they control physical connectivity across modes. While AI provides predictive intelligence, execution depends on reliable rail corridors, inland terminals, and road connections.

Companies such as Arta Rail support this ecosystem by offering stable rail–road transit solutions that integrate smoothly with AI-driven planning. When predictive systems recommend alternative routes or adjusted schedules, inland operators ensure that physical capacity aligns with those recommendations.

This coordination is particularly valuable during maritime disruption. Inland corridors often provide more predictable transit conditions, and AI enhances their effectiveness by optimising timing and load distribution. As a result, multimodal networks remain operational even when ocean routes face volatility.

Internal Link (insert real URL in WordPress):

Arta Rail — The Role of Rail Freight in Strengthening Supply Chain Stability

3.6 AI and Proactive Risk Management

Risk management in logistics has traditionally been reactive. Delays were identified after they occurred, and corrective actions followed. AI reverses this process by forecasting risks before they materialise.

AI-powered dashboards monitor geopolitical alerts, port labour conditions, canal water levels, weather anomalies, and carrier reliability metrics. These systems generate early warnings that allow logistics teams to adjust routes, timing, or capacity in advance.

For example, if weather models indicate a potential storm near a major port, AI suggests alternative discharge locations or adjusted departure schedules. Similarly, if border congestion is predicted, routing plans can be modified before cargo reaches the bottleneck.

This proactive approach reduces uncertainty and stabilises service performance across global networks.

3.7 Long-Term Network Design and Strategic Planning

Beyond day-to-day operations, AI influences long-term logistics strategy. Digital models help companies evaluate where to invest in infrastructure, which corridors to prioritise, and how to balance cost, speed, and risk.

By analysing years of operational data, AI identifies trends in trade flows, corridor performance, and regional demand growth. This supports better decisions regarding warehouse location, terminal development, and multimodal corridor expansion.

As global trade continues to evolve, AI-driven insights become essential for maintaining competitive and resilient logistics networks.

AI’s Impact on Global Freight Networks

| Strategic Area | AI Contribution | Result for Logistics Networks |

|---|---|---|

| Network Design | Identifies optimal corridors | Higher resilience |

| Capacity Planning | Predicts demand and load | Better asset utilisation |

| Risk Management | Forecasts disruptions | Proactive response |

| Visibility | Integrates real-time data | Accurate ETAs |

| Multimodal Coordination | Aligns sea, rail, and road | Stable transit flows |

AI as the Foundation of Future-Ready Logistics

Artificial intelligence is no longer an experimental layer in global logistics. It has become the structural foundation that enables supply chains to operate with speed, accuracy, and resilience in an increasingly unstable world. As trade volumes grow, routes diversify, and disruptions become more frequent, manual coordination alone cannot support reliable freight movement.

Throughout this analysis, one pattern remains clear: AI transforms logistics from a reactive system into a predictive and adaptive network. Predictive analytics improve planning accuracy. Autonomous operations stabilise terminal performance. Digital twins and routing engines strengthen resilience. Real-time visibility connects transport modes into a single operational flow. Together, these capabilities reduce uncertainty and protect supply chains against cascading failures.

For shippers, this evolution delivers tangible value—more reliable ETAs, lower operational risk, and improved cost control. For logistics operators, especially those managing multimodal and inland corridors, AI enhances execution rather than replacing it. Physical infrastructure remains essential, but it performs best when guided by real-time intelligence.

This is where companies like Arta Rail play a critical role. By combining rail–road connectivity with data-driven planning, Arta Rail enables global shippers to apply AI insights across real transport corridors. Inland routes become more predictable, multimodal transfers more stable, and cross-border logistics more resilient.

Looking ahead, AI will not be a competitive advantage reserved for a few leaders. It will become a standard requirement across global logistics. Companies that invest early in intelligent planning, multimodal coordination, and predictive risk management will be better positioned to navigate volatility and maintain long-term reliability.

In this environment, the future of logistics belongs to networks that think ahead, adapt continuously, and execute with precision.