1 .Why Green Logistics Is Becoming a Global Priority in 2025

Green logistics has moved from a long-term ambition to an immediate operational priority. In 2025, sustainability is no longer treated as a branding initiative or optional corporate responsibility. Instead, it has become a core requirement shaping how freight is planned, moved, and managed across global supply chains. Governments, regulators, investors, and customers are all applying pressure on logistics networks to reduce emissions while maintaining reliability and cost efficiency.

This shift is not driven by a single factor. It is the result of overlapping forces that include stricter environmental regulations, rising fuel costs, climate-related disruption, and changing expectations from global shippers. As a result, logistics strategies are evolving toward lower-emission transport modes, energy-efficient infrastructure, and smarter multimodal planning.

1.1 What Green Logistics Really Means in 2025

Green logistics is often misunderstood as simply using cleaner vehicles or offsetting emissions. In reality, it refers to a broader structural transformation of freight networks. In 2025, green logistics focuses on reducing environmental impact across the entire transport lifecycle—from route design and mode selection to warehousing, terminal operations, and cross-border coordination.

Modern green logistics strategies prioritise:

-

shifting cargo toward low-emission transport modes such as rail

-

optimising routes to minimise fuel consumption

-

improving asset utilisation to reduce empty movements

-

integrating sustainability metrics into logistics decision-making

Rather than slowing operations, these measures often improve efficiency. Shorter routes, fewer delays, and better planning reduce both emissions and operational costs. This is why sustainability and performance are no longer seen as opposing goals.

1.2 Regulatory Pressure Is Reshaping Freight Decisions

Environmental regulation is one of the strongest forces accelerating green logistics adoption. The European Union, for example, continues to expand its climate framework through initiatives such as the European Green Deal and Fit for 55. These policies directly affect transport emissions by tightening reporting requirements and increasing the cost of carbon-intensive logistics.

Similar regulatory momentum is visible in other regions. Carbon disclosure requirements are expanding, and large companies are increasingly required to measure and report Scope 3 emissions, which include transport-related activities. As a result, shippers are now evaluating logistics partners not only on price and speed, but also on environmental performance.

This regulatory environment makes low-emission freight solutions more attractive. Rail-based and multimodal corridors gain importance because they offer a measurable reduction in carbon output compared to road-only transport. Consequently, sustainability considerations are becoming embedded in route selection and network design.

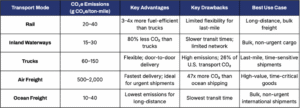

Average carbon-equivalent (CO₂e) emissions by transport mode, showing the environmental efficiency of rail and ocean freight compared to road and air transport.

Source: SeaRates & industry transport emission benchmarks (2024–2025)

1.3 Rail Freight as the Backbone of Sustainable Transport

Among all transport modes, rail freight stands out as one of the most effective tools for reducing logistics-related emissions. Multiple industry studies consistently show that rail produces significantly lower CO₂ emissions per tonne-kilometre compared to road transport. This makes rail an essential component of any green logistics strategy.

However, rail’s value extends beyond emissions alone. Rail corridors offer predictable schedules, high capacity, and reduced exposure to fuel price volatility. When integrated into multimodal networks, rail enables long-distance freight to move efficiently while road transport is reserved for first- and last-mile delivery.

This model is increasingly adopted by global shippers seeking both sustainability and operational resilience. Inland rail corridors, in particular, help reduce congestion at ports and limit reliance on carbon-intensive trucking over long distances.

Operators such as Arta Rail support this transition by providing rail–road connectivity that aligns sustainability goals with practical execution. By enabling cargo to move efficiently across inland corridors, rail-based solutions help global supply chains reduce emissions without compromising reliability.

1.4 Sustainability, Cost, and Operational Efficiency Are Converging

One of the most important developments in 2025 is the convergence of sustainability and cost efficiency. In the past, greener logistics options were often perceived as more expensive. Today, this assumption is increasingly outdated.

Fuel price volatility, congestion-related delays, and inefficiencies in road-heavy networks create hidden costs. Green logistics strategies reduce these risks by improving planning accuracy and network stability. Rail-based and multimodal solutions often lower total cost of ownership by reducing fuel dependency and improving asset utilisation.

In addition, many financial institutions and investors now evaluate companies based on ESG performance. Logistics decisions directly influence these assessments. As a result, sustainability-driven freight strategies support not only environmental goals but also long-term financial stability.

Emissions by Freight Transport Mode (Approximate Averages)

| Transport Mode | CO₂ Emissions (g per tonne-km) | Sustainability Profile |

|---|---|---|

| Road Freight | 90–120 | High emissions |

| Air Freight | 500+ | Very high emissions |

| Sea Freight | 10–40 | Medium emissions |

| Rail Freight | 15–25 | Low emissions |

Indicative Sources for External Linking:

-

European Environment Agency (EEA)

-

International Energy Agency (IEA)

-

World Economic Forum (WEF)

-

International Transport Forum (ITF – OECD)

1.5 Green Logistics as a Strategic Advantage

By 2025, green logistics is no longer about compliance alone. It has become a competitive advantage. Companies that adopt sustainable freight strategies benefit from stronger regulatory alignment, improved brand perception, and more resilient logistics networks.

As global trade continues to face disruption, the ability to move cargo efficiently with lower environmental impact becomes a defining capability. Green logistics combines long-term thinking with operational discipline, and rail-based multimodal networks play a central role in this evolution.

This foundation sets the stage for deeper exploration into how sustainable freight is implemented in practice, including multimodal routing, energy-efficient terminals, and carbon-optimised planning.

2. Core Pillars of Green Logistics in 2025

Green logistics in 2025 is no longer limited to carbon reporting or isolated sustainability initiatives. It has evolved into a structured operational framework built around transport optimisation, energy efficiency, network design, and data-driven decision-making. Companies that treat sustainability as a core logistics variable—not a marketing layer—are gaining measurable advantages in cost control, regulatory compliance, and network resilience.

This section explores the four operational pillars that define green logistics today and explains how they reshape freight planning across global supply chains.

2.1 Low-Emission Transport Mode Optimisation

Transport selection is the single largest contributor to logistics-related emissions. In 2025, sustainable freight strategies begin with mode optimisation, not offsetting.

Rail, inland waterways, and ocean freight remain the most carbon-efficient options for long-distance and bulk transport. Trucks and air freight are still essential, but their use is increasingly restricted to last-mile or time-critical scenarios.

Rather than replacing one mode with another, leading shippers focus on mode balancing. High-volume flows are shifted toward rail and sea, while trucks are used selectively for flexibility. Air freight is increasingly reserved for high-value or emergency shipments only.

This optimisation reduces emissions while also lowering fuel exposure and volatility risk.

Average CO₂e Emissions by Transport Mode (2025 Benchmarks)

| Transport Mode | CO₂e Emissions (g CO₂e / ton-mile) | Sustainability Profile | Typical Use Case |

|---|---|---|---|

| Ocean Freight | 10–40 | Lowest emissions for long-distance | Bulk international cargo |

| Rail Freight | 20–40 | Highly efficient, stable | Long-distance inland transport |

| Inland Waterways | 15–30 | Very low emissions | Bulk, non-urgent cargo |

| Truck Transport | 60–150 | High flexibility, higher emissions | Last-mile, regional delivery |

| Air Freight | 500–2,000 | Highest emissions | Time-critical, high-value goods |

Source reference for citation placement: SeaRates, ITF (OECD), industry benchmarks

This data explains why rail-based corridors are central to green logistics strategies. Inland rail operators enable companies to decarbonise without sacrificing reliability.

2.2 Energy-Efficient Warehousing and Terminals

Beyond transport, logistics hubs play a growing role in sustainability performance. Warehouses, dry ports, and terminals consume large amounts of energy, particularly for lighting, heating, cooling, and material handling.

In 2025, green logistics hubs focus on energy efficiency rather than expansion. Key improvements include:

-

LED and smart lighting systems

-

Energy-efficient HVAC infrastructure

-

Solar-powered terminals and rooftops

-

Electric and hybrid yard equipment

-

Automated energy monitoring systems

These upgrades reduce emissions while also lowering operating costs. Importantly, they improve operational predictability, since energy volatility becomes less of a risk factor.

Rail-connected inland terminals benefit disproportionately from these upgrades because energy efficiency aligns directly with high-throughput, predictable cargo flow.

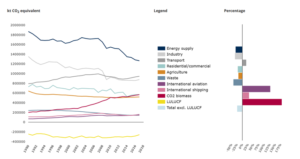

Global CO₂-equivalent emissions by sector show the growing contribution of transport, international shipping, and aviation—explaining why carbon cost is becoming a critical factor in freight economics.

Source: International Energy Agency (IEA) / IPCC sectoral emissions data

2.3 Sustainable Multimodal Network Design

Sustainability is not achieved by optimising individual routes—it requires network-level design.

Green logistics leaders redesign their freight networks to reduce unnecessary distance, avoid congestion-prone hubs, and minimise empty repositioning. Multimodal routing plays a critical role in this process.

Instead of relying on a single dominant corridor, companies build distributed route portfolios that combine sea, rail, road, and inland hubs based on carbon efficiency and reliability.

This approach delivers three advantages:

-

Lower total emissions across the network

-

Reduced exposure to chokepoints

-

Greater flexibility during disruptions

Inland rail corridors are especially valuable here because they allow companies to bypass congested ports and rebalance flows inland.

Sustainability Impact of Network Design Choices

| Network Design Strategy | Emission Impact | Operational Benefit |

|---|---|---|

| Single-route dependency | High risk, higher emissions | Vulnerable to disruption |

| Multimodal diversification | Lower emissions | Greater resilience |

| Inland hub integration | Reduced last-mile distance | Faster clearance and transfer |

| Rail–road combinations | Optimised fuel usage | Cost and emission balance |

This shift explains why multimodal planning is now a core ESG requirement, not an optional optimisation.

2.4 Data-Driven Carbon Planning and Measurement

Green logistics in 2025 is measurable. Companies no longer rely on estimated averages or annual reports. Instead, they track carbon performance at shipment level.

Advanced logistics platforms integrate:

-

Mode-specific emission factors

-

Route-level distance calculations

-

Fuel consumption data

-

Load optimisation metrics

This allows companies to compare routing options based on carbon intensity, not just cost or speed.

As a result, sustainability becomes a decision variable, not a reporting outcome.

Operators with strong inland infrastructure—such as rail corridors—enable shippers to apply these insights practically. When data highlights a lower-emission route, the physical capacity must exist to execute it.

This is where rail-based and multimodal providers play a decisive role.

3. How Companies Operationalise Green Logistics in 2025

In 2025, green logistics is no longer a conceptual strategy discussed only at board level. It has become an operational discipline that shapes how freight is routed, handled, stored, and monitored on a daily basis. Companies that succeed in this transition are those that convert sustainability goals into measurable logistics actions across networks, infrastructure, and execution layers.

3.1 Building Low-Emission Multimodal Transport Networks

The foundation of green logistics execution lies in multimodal network design. Instead of optimising routes solely for speed or cost, companies now evaluate freight flows based on emissions intensity, congestion risk, and long-term stability.

Rail-based corridors play a central role in this shift. Rail transport produces significantly lower CO₂ emissions per ton-kilometre compared to long-haul trucking, while offering higher energy efficiency and strong compatibility with electrification. When combined with maritime and short-haul road transport, rail creates a balanced, low-emission backbone for long-distance freight.

Multimodal optimisation focuses on:

-

Reducing high-emission road segments

-

Limiting empty container repositioning

-

Avoiding congested maritime chokepoints

-

Aligning routes with electrified infrastructure

As a result, logistics planning becomes dynamic rather than linear. Routes are constantly evaluated based on environmental impact, reliability, and regulatory exposure.

Emissions Intensity Across Multimodal Transport Chains

| Transport Chain | Typical Emissions Profile | Sustainability Impact |

|---|---|---|

| Sea + Rail + Short-Haul Truck | Low | High sustainability, stable compliance |

| Sea + Long-Haul Truck | Medium–High | Higher emissions, higher regulatory exposure |

| Rail + Road (Balanced) | Low–Medium | Efficient inland distribution |

| Air + Road | Very High | High carbon cost, limited use cases |

Indicative ranges based on ITF–OECD and industry benchmarks

3.2 Green Warehousing and Terminal Operations

Sustainability does not stop at transport. Warehousing, inland terminals, and intermodal hubs represent a major share of logistics-related emissions. In response, companies are redesigning facilities to operate with lower energy intensity and higher operational efficiency.

Modern green logistics facilities integrate:

-

Solar panels and renewable energy systems

-

Electrified handling equipment and cranes

-

Energy-efficient lighting and climate control

-

Smart yard-management systems

Data-driven layout optimisation reduces unnecessary cargo movement inside warehouses. Fast-moving goods are positioned closer to outbound gates, while AI-based forecasting synchronises inbound arrivals with dispatch schedules. This minimises idle time, congestion, and energy waste.

In 2025, sustainability certification for logistics facilities is becoming standard practice, particularly for large distribution centres and inland terminals supporting multimodal corridors.

3.3 Sustainable Fleet and Equipment Transitions

Fleet transformation is one of the most visible elements of green logistics execution. While full electrification of long-haul freight remains challenging, companies are making targeted upgrades where sustainability gains are most effective.

Key transitions include:

-

Electric trucks for last-mile and regional distribution

-

Hybrid or electric yard tractors

-

Shore power connections at ports

-

Electrified cranes and terminal equipment

Rather than replacing entire fleets, companies focus on incremental upgrades aligned with operational realities. This approach delivers measurable emissions reductions while maintaining reliability and cost control.

Fleet sustainability in 2025 is defined by optimisation—not disruption.

3.4 Carbon Measurement, Visibility, and Reporting

Operational sustainability requires precise measurement. As a result, carbon tracking is now embedded directly into logistics management systems. Emissions are calculated per shipment, per route, and per mode, allowing companies to compare operational choices in real time.

Carbon visibility enables logistics teams to:

-

Select routes based on emissions impact

-

Support Scope 3 emissions reporting

-

Prepare for regulatory audits

-

Identify inefficiencies across networks

Carbon data is increasingly evaluated alongside cost and transit time. A route that appears cheaper in the short term may carry higher long-term exposure due to carbon pricing or regulatory penalties.

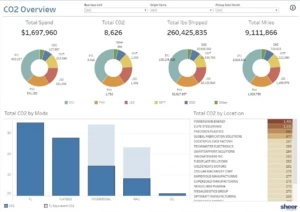

CO₂ emissions and sustainability performance dashboard used for monitoring environmental impact across logistics and supply chain operations.

Source: Sheer Logistics – Supply Chain Emissions & Analytics Framework

Key Operational Levers for Green Logistics Execution

| Operational Area | Sustainability Lever | Practical Outcome |

|---|---|---|

| Routing | Rail-first multimodal planning | Lower emissions, stable ETAs |

| Warehousing | Energy-efficient facility design | Reduced energy consumption |

| Fleet | Electrified short-haul equipment | Lower fuel and maintenance costs |

| Data | Carbon tracking per shipment | Accurate ESG reporting |

| Terminals | Electrified handling systems | Faster throughput, lower emissions |

3.5 The Strategic Importance of Inland Rail Corridors

Inland rail corridors are essential to scaling green logistics beyond pilot projects. While maritime transport remains unavoidable for global trade, inland connectivity determines how sustainably cargo moves once it reaches land.

Rail corridors:

-

Absorb cargo from congested ports

-

Reduce dependency on long-haul trucking

-

Stabilise emissions across regional flows

-

Improve schedule predictability

When integrated into multimodal networks, inland rail becomes a structural advantage. Operators such as Arta Rail support these strategies by providing rail–road connectivity that aligns sustainability goals with operational execution. Their corridors enable shippers to reduce emissions exposure while maintaining reliability across regional and cross-border routes.

3.6 Aligning Sustainability with Commercial Performance

One of the most important developments in 2025 is the realisation that green logistics improves commercial performance when executed correctly. Lower fuel volatility, reduced regulatory exposure, and predictable routing contribute to long-term cost stability.

Companies that operationalise sustainability effectively benefit from:

-

Stronger resilience during disruptions

-

Improved access to ESG-driven contracts

-

Higher transparency for customers and investors

-

Reduced compliance risk

Green logistics succeeds when sustainability metrics are embedded into everyday planning rather than treated as a parallel initiative.

Green Logistics as a Practical Operating Model

By 2025, green logistics has moved decisively from ambition to execution. Regulatory pressure, economic incentives, and operational realities now converge toward low-emission freight networks. Companies that adapt early gain advantages not only in sustainability metrics, but also in resilience, predictability, and long-term competitiveness.

Rail-based and multimodal strategies form the backbone of this transition. Supported by energy-efficient infrastructure, transparent data, and intelligent network design, green logistics becomes a practical operating standard rather than a future aspiration.

For global shippers and logistics providers alike, the conclusion is clear:

sustainable freight is no longer optional—it is the foundation of modern logistics performance.